Benefiting from the launch of 100 billion RMB funds for “Aero engine and gas turbine Project”, the Superalloy industry will embrace an explosive growth opportunity. According to the “Aero engine and gas turbine Project”, the Chinese government will invest 100 billion RMB funds to support the development of aero engine and gas turbine industry. While the key point of developing aviation industry is the power, the materials contribute most in the development of the power. Aero engines and gas turbines as the protagonist of the project, account for nearly 75% of downstream applications of superalloy materials, which will boost the whole superalloy industry. A huge historical opportunity could be foreseen for the superalloy industry.

Superalloy is widely used in the aerospace industry, automotive, power, glass manufacturing, atomic energy and other industrial fields. Aerospace and power are the main downstream markets for superalloy, accounting for more than 70% of the total market. Except used in aero engines and ship gas turbines, superalloy also could be used in automotive turbochargers, nuclear power, petrochemical, metallurgy, textile, glass manufacturing and many other civilian fields.

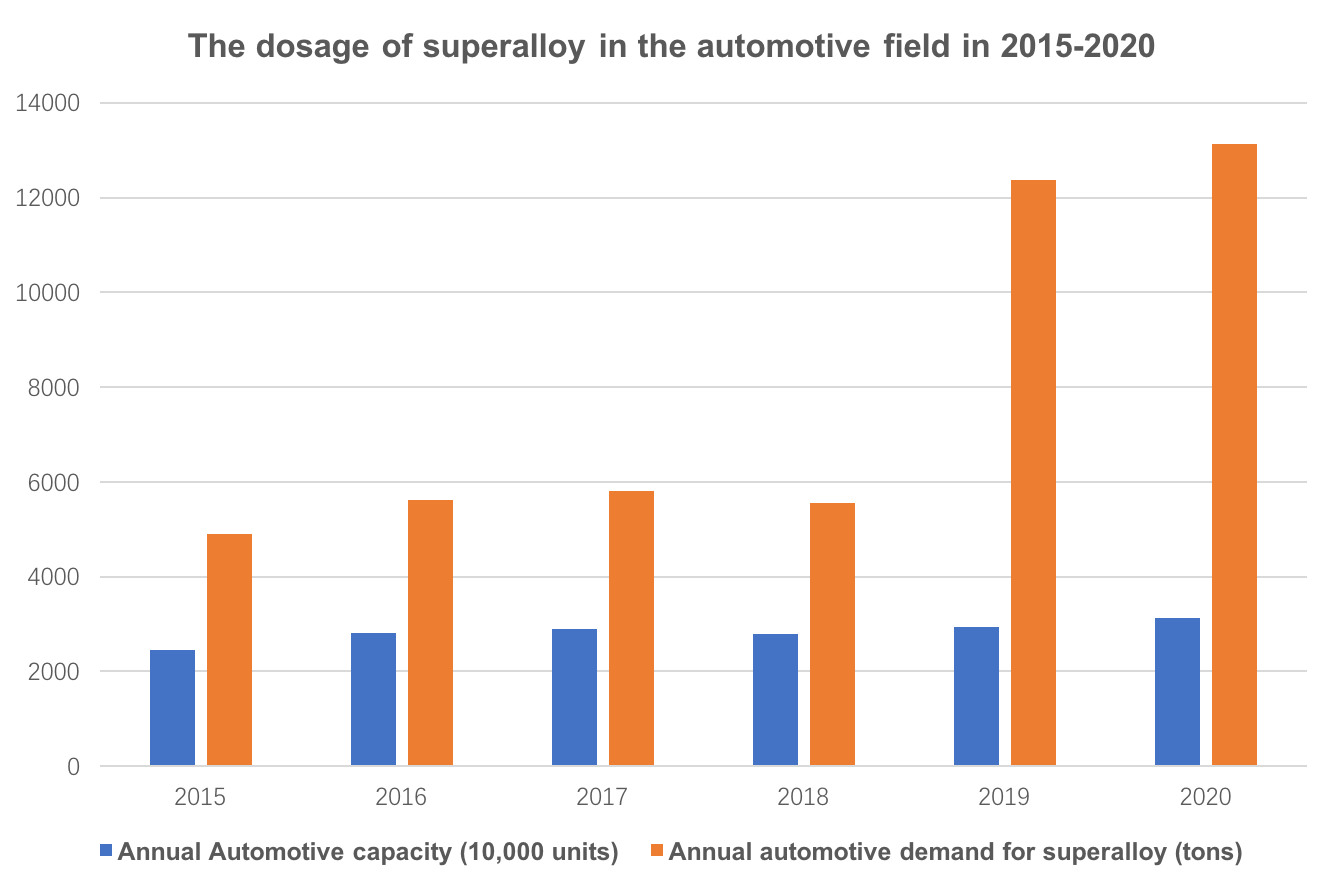

First industry market prospect: In 2020, the demand of superalloy from automotive exhaust gas turbocharger turbine would reach 13,100 tons

Automotive exhaust gas turbochargers are also essential applications for superalloy materials. The production of exhaust gas turbocharger turbine has been more than 60 years in foreign countries.At present, in foreign countries, the heavy-duty diesel supercharger configuration rate is 100% as well as the constant proportion increase of small and medium-sized diesel engines. For example, the United Kingdom, the United States, France and other countries have reached around 80%. Exhaust gas turbochargers own the advantages of reducing harmful emissions and noise pollution, improving mechanical efficiency and power. For now, the turbine impellers used by turbocharger manufacturers in China are mostly nickel-based superalloy turbine impellers, which together with the turbine shaft and the compressor impeller form one rotor.

In 2018, there are 27.809 million vehicles been produced in China. Based on the calculation of around 2 tons of superalloy usage per 10,000 car turbochargers, would reached 5,562 tons; With the expect of the increase in vehicle production (6% of long-term growth rate), as well as the enhance of the permeability of Chinese automotive turbochargers, and replacement of iron-based components such as engine exhaust pipes, by 2020, the demand of superalloys for every 10 thousand automobiles will reach 4.2 tons. Corresponding to the total dosage of 13,100 tons, and the compound growth rate of 6 years will reach 17.8%, which will be the most rapid growth civil field of superalloys in the near future.

courtesy to Frontier industry research institute

Second industry market prospect: The superalloy industry will benefit first from the lanch of the 100 billion RMB “Aero engine and gas turbine Project”

According to the information from the Ministry of Industry and Information Technology, during the "13th Five-Year Plan" period, China will launch the“Aero engine and gas turbine Project” to have brake through in the key technologies of aero engine and gas turbine. Plus with promoting the development of large passenger aircraft engines, advanced helicopter engines, heavy-duty gas turbines, etc., the independent basic research and technology, product development and industrial systems of aero engine and gas turbine will be established.

Benefiting from the launch of 100 billion RMB funds for “Aero engine and gas turbine Project”, the superalloy industry will embrace an explosive growth opportunity. According to the project plan, the Chinese government will invest 100 billion RMB to support the development of the aero engine and gas turbine industry, which account for nearly 75% of downstream applications of superalloy materials. A huge historical opportunity could be foreseen for the superalloy industry.

Market development trend: Industry oligopoly structure will be continued

The superalloy industry shows strong monopoly and stability, therefore the industry leaders will continue to enjoy the long-term dividends brought by industry barriers. The barriers mainly include technical barriers, market access barriers, quality standard barriers, and accumulative curves, which make new companys face higher entry and time costs. Due to the existence of special attributes of the industry, no matter from foreign experience or domestic superalloy segment and major players, it could be found that the industry presents oligopoly properties with only 1-2 oligopolistic manufacturers’ existence in each country.

About Sino-Euro Materials Technologies of Xi’an Co. Ltd (Sino-Euro)

Sino-Euro Materials Technologies of Xi'an Co., Ltd (Sino-Euro), a subsidiary of the Northwest Institute for Non-ferrous Metal Research. Sino-Euro is on the cutting edge of technology. Specializing in powder metallurgy, Prealloy Spherical SS-PREP® Powder, Additive Manufacturing Bar&Wire, and HIP service & components.

For more information visit: www.c-semt.com

Предыдущая страница: Пока нет содержания

Следующая страница: New titanium beta 21S powder for AM

Навигация

Следование за нами